Camper Trailer of the Year 2023 – Ultimate Campers Xscape

Off the back of the popularity of the X25 came the Ultimate Campers Xscape. This camper trailer comes with off grid options you can’t get

LUXURY

AUSTRALIA

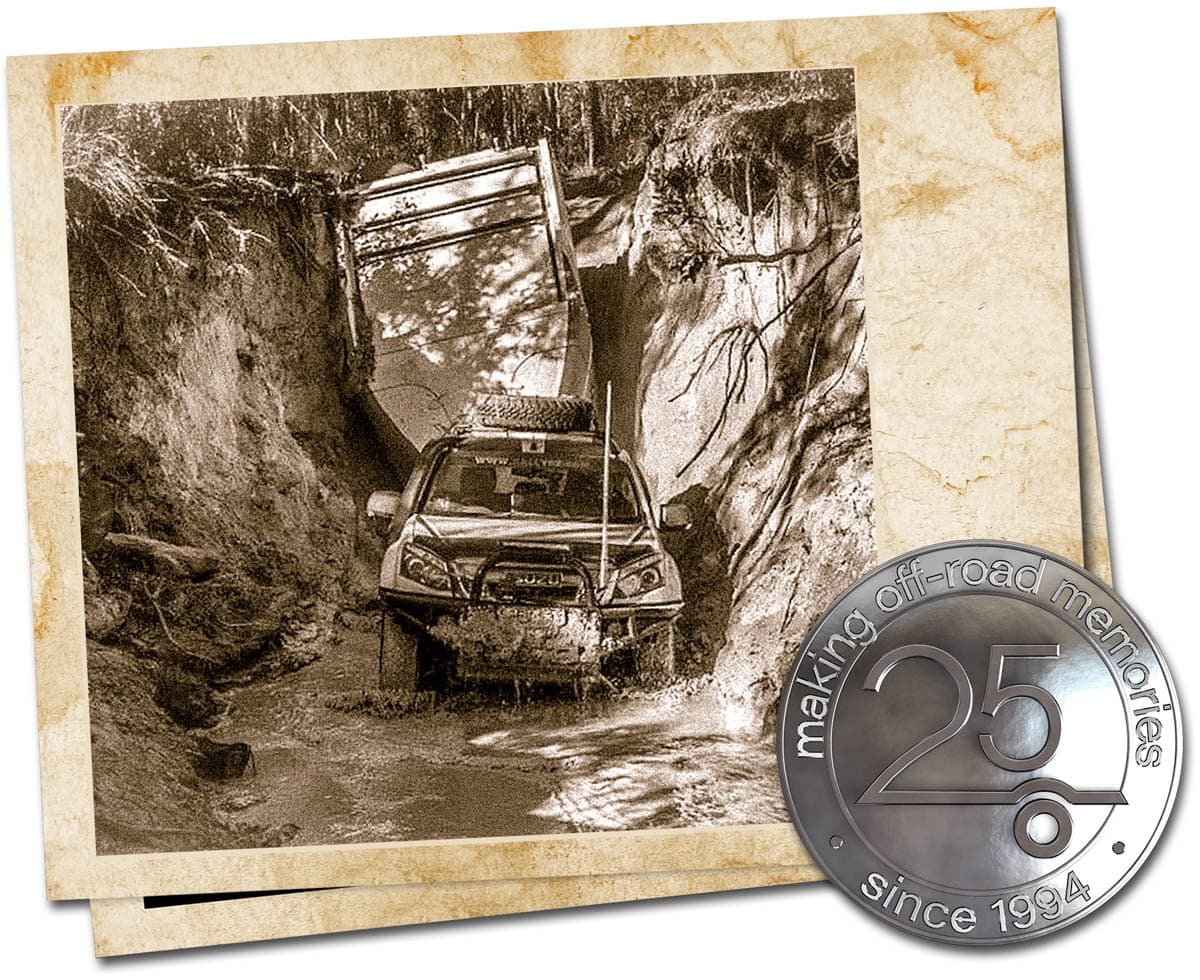

We’ve been making Australia’s best luxury off-road camper trailers for over 25 years. They’re lightweight, extremely durable, exceptionally comfortable and made in Australia for Australian off-road adventures.

OR

Embark on the ultimate journey of luxury and adventure with Ultimate Camper’s unrivalled luxury camper trailers. Our camper trailers are the embodiment of innovation, pushing the boundaries of off-road exploration and providing options you won’t find anywhere else. Designed to cater to the most discerning outdoor enthusiasts, our campers continuously evolve, ensuring you experience the very best that camping has to offer.

The heart of our campers lies in their remarkable off-road capabilities. With their towering clearance, agile manoeuvrability, and slender bodies, our camper trailers glide over even the toughest terrain. Embrace the spirit of adventure as you conquer challenging trails, access hidden gems, and relish in the unparalleled freedom that our campers provide. Check out our diverse range of camper trailers, each designed to cater to your specific desires for the ultimate adventure. The Xscape, Nexus, GT, Xplore, and Xtrk+ campers stand as a testament to our commitment to delivering excellence in every aspect of camping.

Picture this: a camper trailer that takes you off the grid, enabling you to escape to remote and breathtaking destinations. Our campers boast a range of off-grid options that let you immerse yourself in the beauty of nature while enjoying the comforts of a five-star accommodation. Whether you’re camping in the heart of the outback or navigating rugged terrain, our campers are built to exceed your expectations.

Designed with the avid explorer in mind, our luxury camper trailers offer the perfect harmony of comfort, durability, and style. Whether you’re embarking on a soul-stirring solo journey or embarking on a family expedition, our campers are ready to accommodate your every need. Experience the very best in off-road camping with Ultimate Camper’s luxury trailers – the ultimate fusion of luxury and adventure, waiting to take you on the journey of a lifetime.

For over a quarter of a century, Ultimate Campers has been the undisputed leader in the Australian camper trailer industry. Established in 1994, our journey has been nothing short of extraordinary. With 25+ years of experience under our belt, we’ve not only withstood the test of time but have continually pushed the boundaries of innovation and excellence in the field of off-road campers.

Trust is at the core of our relationship with our customers. When you choose an Ultimate Camper, you’re not just buying a product; you’re investing in a legacy of excellence and adventure. Our campers are built to withstand the harshest conditions, ensuring your peace of mind when you’re far from civilisation.

When it comes to camper trailers in Australia, no name carries as much weight as Ultimate Campers. Our journey began with a simple yet profound vision – to enable adventurers to explore the rugged terrains of Australia without compromising on comfort and luxury. Over the years, our unwavering commitment to this vision has transformed us into the country’s premier manufacturer of luxury camper trailers.

With 25+ years of experience, we’ve accumulated a wealth of knowledge that is unparalleled in the industry. Our team comprises seasoned experts who live and breathe camper trailers. We understand the unique challenges and demands that the Australian landscape presents, and this expertise is deeply embedded in every camper trailer we create.

We offer a range of five camper models with the same base configuration creations, constantly improving and innovating with currently over 40 advancements to our models and many more to come.

At Ultimate Campers, innovation is in our DNA. We’re not content with resting on our laurels. Over the years, we’ve made over 40 advancements to our line of camper trailers. These improvements range from cutting-edge materials to state-of-the-art technology integration. We’re continually pushing the boundaries to ensure that our customers have access to the best camper trailers that Australia has to offer.

Our dedication to innovation doesn’t just make our campers better; it also makes your adventures safer and more enjoyable. We understand that off-road exploration can be challenging, and that’s why we’re committed to providing you with the tools you need to conquer any terrain.

As Australia’s No. 1 manufacturer of off-road campers, we don’t take our responsibility lightly. Our commitment to quality, luxury, and innovation is unwavering. Explore the beauty of Australia with Ultimate Campers.

For more than 25 years, Ultimate Australia has listened and worked with our customers, fine-tuning our campers, experimenting and innovating. To us, they are not customers, they are members of an exclusive club.

Every so often, innovation takes a massive leap forward. And with this leap, the brand-new Ultimate NEXUS 360 was born.

We’ve raised the bar once more with this flagship camper trailer. It has everything you have come to expect from an Ultimate Off-road Camper trailer – light weight and nimble yet extremely durable, aerodynamic contours leading to a more fuel-efficient adventure, surprisingly spacious and incredibly comfortable!

Customise your camper trailer

The new show room is outstanding, very impressive which matches the service you receive ???? ????

The factory where the Ultimate is manufactured. All the staff wonderful and welcoming. Loving our Xterran.

Fantastic service. Our camper is our little home away from home so pleased an happy with the repairs done after it got flooded. Jason, Grant an staff were so great to deal with and very friendly even through their business takeover challenges very impreesed guyz keep up the good work Paula an Maurie enjoying the great outdoors once again ????????????????????⛺*****

Having spent 10 weeks of our first year owning our Xplor GT living in our camper on numerous trips, we can honestly say the Ultimate is an awesome camper. We are a family of 4 and the king bed and lounge bed make it super comfortable. It’s easy to forget that it is trundling along behind you, it’s just a beautifully engineered machine.Love it.

Awesome product that is so well designed and easy to use. Love that it is made in Australia using high quality materials. Andrew, John, Jenny, Nicky and Steve really looked after us. This camper really lives up to the hype, don't hesitate to buy one! Plus the community of owners is fantastic

Fantastic camper! Quality build. Great service. And a wonderful family of owners to communicate with and get ideas from.

The most practical well thought out camper on the market period! Handles any terrain with ease and is a pleasure to watch in the rear view mirror. Plus it’s soooo light! And easy to tow! And don’t even get me started about how easy it is to set up and pack up! The name is a fact! Ultimate off-road campers are the Ultimate Camper! Second to none!

Bought our pre loved Ultimate from the factory a few months ago and we absolutely love it. The staff at Ultimate where extremely helpful and professional to deal with even supplying lunch for us.

Love my ultimate camper, it has done 23,000km around Australia on a 6 month trip, 2 adults and a 2year old. Crossed the simpson, Cape York, Kimberlys, love it. Wouldn't have anything else.

from the moment we decided to order an Ultimate all the way through to its delivery, walk through and use Ultimate have been awesome to deal with. A top qaulity product that can go where ever you point your 4wd without any issue.

Ultimate Offroad Camper, a brilliant camper so easy to use, tows like a dream and can be handled easily.

Have traveled this amazing country with our ultimate for the past 8 years an amazing camper could never wish for anything better.

fantastic Aussie business. building a world leading unique style camper trailer, all made in Australia, ideally suited to Australian conditions, these trailers have proven themselves time and again over many years. a dedicated fan base has grown because of the amazing service shown by the company, and the outstanding capabilities of their trailers. these guys really know what they are doing, and the quality of the trailer, the impeccable design and the passionate fan base is testamount to this great Australian company.

Looking at campers, the showroom was good size to see the product, well appointed with lounge and tea/coffee which is needed as a visit takes some time. And very importantly, the sales person John was excellent with so much knowledge as a long time user if the product.

Took delivery of a new Xterran recently and just completed a nice little 5000 jaunt through outback NSW and QLD. Recent rain guaranteed lots of mud , potholes and dodgy wash-outs. We are staggered at the offload ability and poise of our new Ultimate - Insanely great ! So easy to put up (maybe 7 minutes) and just as easy to break camp in the morning and get moving. Honestly have to say world class design and quality and if that weren't enough the follow up and service by the awesome staff at Ultimate is also amazing. If you are genuinely looking and thinking about an off road trailer then seriously consider the new Xterran - It sure isn't the cheapest but you can see and feel the build quality everywhere you look ! Massive fans - Highly recommend.

Been an Ultimate owner for over thirteen years!! The best of the best. Now in a Nautilus.

Incredible service and amazing campers must seen to be believed - quality is off the charts and the features for the price leaves you feeling like you have scored a bargain. I have upgraded to an Xterran From a conqueror 330 and the towing difference is night and day the ultimate does not pitch and you hardly notice it is even there compared to the Conquror. The whole ultimate experience was to say the least magnificent. I arrived in the morning for my handover to be greeted by smiling faces and a coffee, followed by a tour of the factory and then a very thorough 3 hour setup and tips session that was invaluable. Then at lunchtime out come a huge platter of sandwiches and drinks while John (my hand over expert) explains just how incredible these campers are off road. A huge thanks to EMILY for the top notch service and keeping me up to date during the purchasing process and to John who is a very passionate Ultimate camper expert - on the whole a 5 star service experience backed up by an insanely high quality build all made locally in rural NSW - a huge credit to the Ultimate team for building world class bulletproof campers all made by Local Aussie labour and I must repeat again the quality of finish and the sealing, hinges, fitment of all components is faultless - bring on the Simpson and Canning ! Upon returning home to MELBOURNE my 7 year old son took one look inside and and out and after a long pause said " Dad, this camper trailer is fully Black Ops ! How long is it until school holidays " Sent from my iPad

Off the back of the popularity of the X25 came the Ultimate Campers Xscape. This camper trailer comes with off grid options you can’t get

Jockey wheel range measured at the tow vehicle’s tongue upper surface – the mounting face for the DO35 pin: Trailer Ball Height Range Standard and

A statement regarding our new servicing locations; As of 1st May 2022, Ultimate Campers will be restructuring our service department. This decision was not made

Fill in the form below and our team will reach out to you within 1 business day.

Speak to the Ultimate Campers Team Today

Phone: 1300 500 077

Email: [email protected]

Ultimate Campers would like to acknowledge the Traditional Owners of the land. We pay our respects to their Elders, past and present, and the Aboriginal Elders of other communities who may be here today. We celebrate the stories, culture and traditions of Aboriginal and Torres Strait Islander Elders of all communities who also work and live on this land.

NOTE: Images may show previous, customised or export models. Please check with your sales rep for current inclusions.

Become part of The Ultimate Circle - a club where you will receive exclusive, never before seen content, updates & releases before anyone else, behind the scenes content and much more.

Fill out the form below and one of our team will call you back within 24 hours.

Typically replies within an hour

I will be back soon